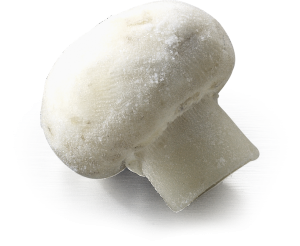

Available in various sizes

Cap size

Various cap sizes from

20 mm - 80 mm

Slice thickness

Various slice thicknesses

from 4 mm - 9 mm

Pack size

Various packagings from

bags of 450 g to

octabins of 850 kg

Frozen mushrooms applications

Pizzas, mono bags, soups, sauces, mixes, ready meals, hamburgers, pasta, sandwiches…

Our Frozen Factory

Champi-mer, the production facility for frozen mushrooms located in Kesteren, the Netherlands. The process is fully automatic: cooling, washing, cutting and onto a deep-freezing conveyor belt where the temperature is minus 40 degrees Celsius. A strong air flow prevents the mushrooms from sticking together. Within half an hour, they come out of the tunnel and go into their packaging.

Have a look at Champi-mer.