Whole

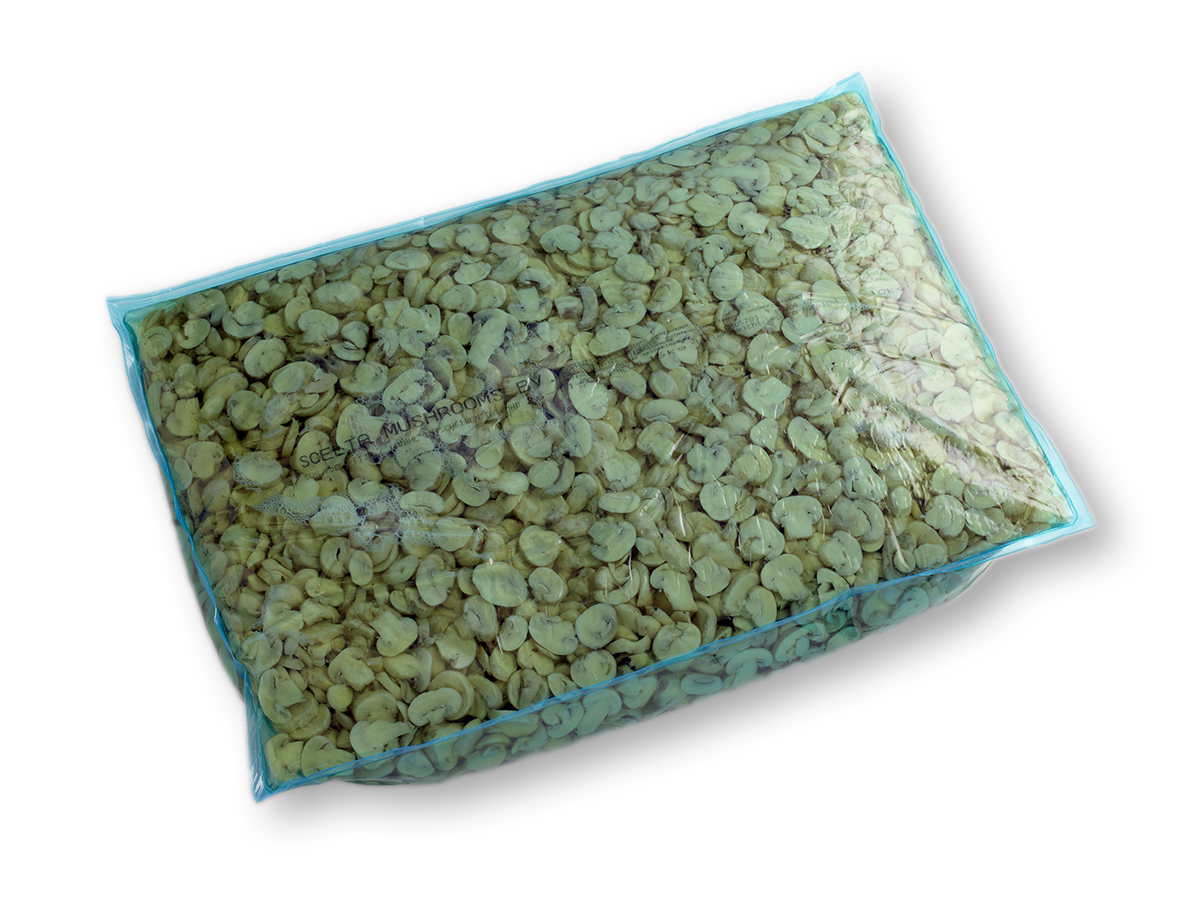

Our polybag

Sliced

Available in various sizes

Cap size

Various cap sizes from

20 mm - 80 mm

Slice thickness

Various slice thicknesses

from 4 mm - 9 mm

Pack size

Standard packaging includes

10 kg polybags

Preserved mushrooms applications

Burgers, soups, sauces, pizzas, wraps, spreads, paté, salads, pastries, pastas, risotto, omelettes

Our Polybag Factory

Our polybag factory Comé is located in Horst. After the mushrooms have been picked at the farm, the crates are wheeled into the hall as quickly as possible. The mushrooms are immediately placed in a vacuum where they suck up water. Mushrooms contain quite a bit of air: by placing them into a vacuum this gets replaced by water, making sure they won’t float to the surface when in the blanching kettle. Blanching (heating something in almost boiling water) is the first step to prolonging the mushrooms’ shelf life.

Looking for more information or interested in a sample? Contact us below.